Services

Quality is at the heart of our philosophy

We provide complete design freedom, allowing our customers to customize their products with a wide variety of shapes and functionalities. Every step of our production cycle is meticulously supervised by our technical staff, from in-house mold manufacturing to delivery of the finished product.

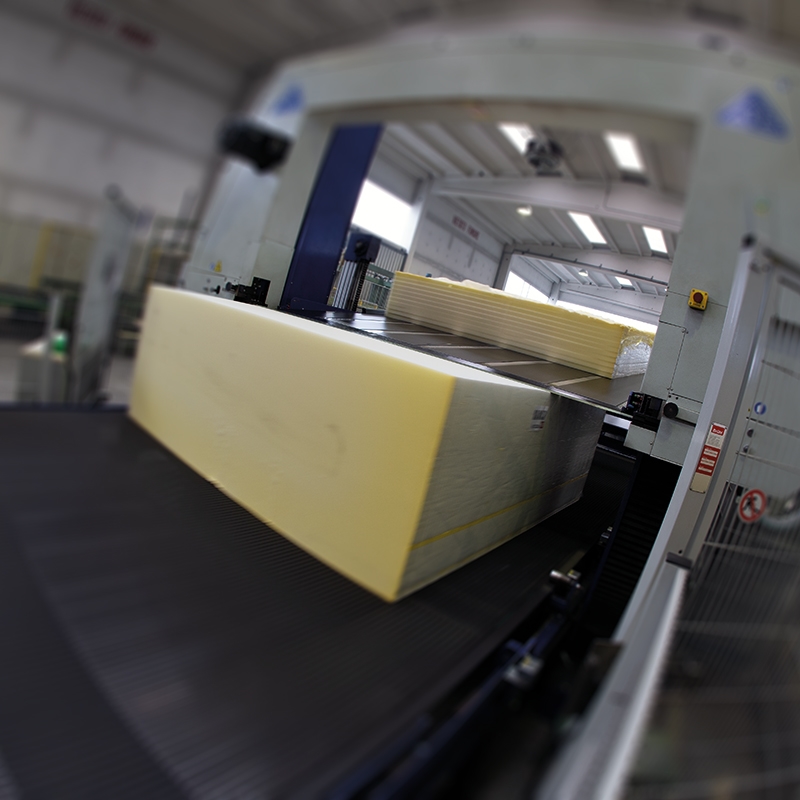

Block polyurethane

The continuous production of flexible expanded polyurethane minimizes material waste and ensures optimal consistency and uniformity in block formulation. Rigorous quality controls, performed at every stage from raw materials to storage, ensure that each batch perfectly meets customers' specific requirements. Customers benefit from complete flexibility to customize shapes and dimensions. The advanced techniques used allow for precise squaring of blocks, optimizing cuts and reducing costs while meeting custom shape needs.

Polyurethane sheets

Thanks to state-of-the-art cutting equipment, Linea Confort can produce large quantities of straight sheets, offering a variety of densities and dimensions tailored to each customer's specific needs.

Template cutting

The contour cutting machine allows precise manual cutting of complex shapes using custom templates. Ideal for manufacturing custom foam parts, it offers great flexibility in creating specific shapes. This artisanal process optimizes cuts, limits material waste, and meets the varied needs of the bedding, furniture, or special technical applications sectors.

Continuous sheet rolls

Continuous production allows manufacturing polyurethane blocks of different lengths. The 60-meter long blocks (also called long slabs) are used for foam roll production. A long slab is placed on a specialized cutter that joins and glues the ends of the slab to form a large ring (ellipse). Midway, this ring meets a shear with electronic control that cuts the slab to create a foam roll (continuous sheet). Depending on the type and density of the polyurethane, the rolls can range from a few millimeters to about ten centimeters in thickness. The height of the rolls varies from 1.5 meters to over two meters, with extremely precise thickness tolerance, measured in tenths of a millimeter.

Leather and fabric sofa manufacturing

Leather and fabric sofa manufacturing combines craftsmanship and technology to deliver high-quality products. Each sofa is designed from carefully selected materials, ensuring comfort and durability. The process includes material cutting, assembly of a robust structure, and optimized padding to guarantee comfortable seating. Available in various styles and finishes, each sofa combines aesthetics and functionality to meet every customer's needs.

Viscoelastic pillows

Linea Confort offers a wide range of viscoelastic pillows designed to provide optimal comfort and perfect rest. Through a selection of high-quality products, each pillow is chosen to meet our customers' specific needs, offering personalized support for restorative sleep. We take pride in providing reliable products, carefully selected from trusted manufacturers, ensuring comfort and durability.

0

Clients

0

Years of experience

0

Product types