Foam

Flexible Polyurethane Foam

Through the use of advanced production technologies and a constant commitment to researching innovative, environmentally friendly, high-performance, and reliable solutions, Linea Confort offers a wide range of flexible polyurethane foams available in blocks, sheets, and rolls.

POLILATEX® STANDARD RANGE

Conventional open-cell microcellular foams offer a wide range of densities, from 18 to 40 kg/m³. These foams, made from basic polyurethanes, ensure optimal comfort and remarkable resistance to long-term deformation.

POLILATEX® SPECIAL RANGE

High-tech conventional open-cell microcellular foams consist of polyurethanes with properties adapted to various technical applications. They are used in sectors such as soundproofing, packaging, construction, and footwear, while also being employed for specific uses in furniture and bedding.

POLILATEX® FLAME RETARDANT

Conventional open-cell microcellular foams are specially designed to meet international standards requiring high flame resistance, as well as low levels of smoke opacity and toxicity. These foams are developed for applications in public environments such as hospitals, prisons, and hotels, where safety requirements are particularly strict.

OLMOSOFF®

Conventional open-cell microcellular foams, featuring cutting-edge technology, represent a major innovation. They are distinguished by an excellent elasticity index, optimal comfort, low deformation, high resistance to tearing and traction, as well as remarkable breathability. Available in a range of densities from 12 to 45 kg/m³, these foams generally exhibit low load-bearing properties. They are suitable for use in the furniture and bedding sectors.

HIGH COMFORT RANGE

Conventional open-cell microcellular foams are characterized by exceptional performance in terms of elasticity and non-deformability, while meeting high comfort requirements. These properties allow these polyurethanes to satisfy the most demanding needs in the furniture and bedding sectors.

H.R. / HIGH RESILIENCE

H.R. (High Resilience) open-cell microcellular foams provide an alternative to classic conventional foams. They stand out for superior performance in terms of elasticity index and breathability, significantly enhancing comfort levels. Additionally, they are distinguished by their excellent flame resistance, enabling them to meet the most common international fire safety standards.

B.S. RANGE

Conventional and H.R. (High Resilience) open-cell microcellular foams form a complete range specifically designed to pass very rigorous flame resistance tests, such as B.S. 5852 CRIB V. This range includes the Polilatex family (C.M. range) and the Elast Performance FR range. Thanks to the wide variety of foams offered, it provides solutions tailored to all needs in the upholstered furniture sector, particularly when specific fire resistance requirements are mandatory.

HIGH TECHNOLOGY RANGE

H.R. (High Resilience) open-cell microcellular foams embody the excellence of the OLMO range. Designed to offer optimal comfort while minimizing environmental impact, they comprise the Ecoelast, Polilatex HT, and Lympha families. The latter family is distinguished by the use of raw materials of plant origin, positioning these foams at the forefront of expanded polyurethane technology. They thus represent an innovative and environmentally friendly solution.

VISCOELASTIC RANGE

Conventional and H.R. (High Resilience) open-cell microcellular foams are slow-recovery foams with a very low elasticity index, capable of perfectly conforming to the body shape for optimal support. They thus avoid the excessive pressure often associated with traditional foams. These characteristics make them a particularly popular choice in the bedding sector, where comfort and support are essential.

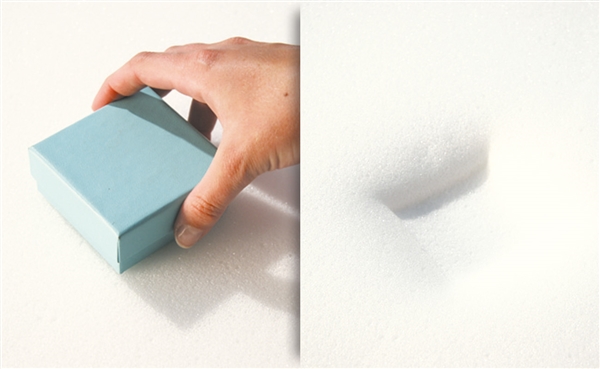

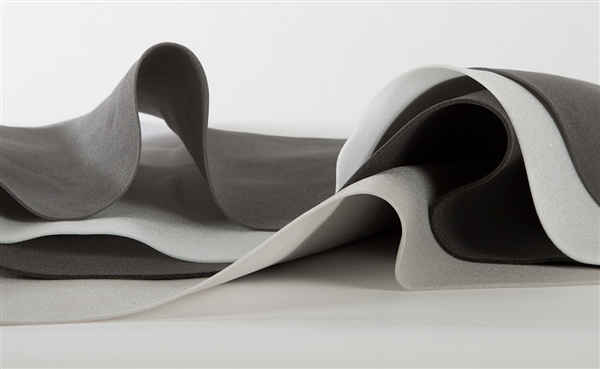

CONTINUOUS SHEET ROLLS

Continuous production allows for the manufacturing of polyurethane blocks of varying lengths. The 60-meter long blocks, known as "long loaves", are primarily used for producing foam rolls (continuous sheets). Depending on the foam types and densities, it is possible to obtain rolls with thicknesses ranging from slightly more than one millimeter up to about ten centimeters. Thickness tolerances are controlled with precision to the tenth of a millimeter, ensuring high consistency and quality of the finished products.

+0

Clients

0

Years of experience

0

Product Types